Mission critical systems as in the Aerospace, Military, Medical and Industrial industries cannot be allowed to fail. Many of these industries utilize legacy systems designed years or decades ago but are still in use today. These legacy systems require constant support and updating, with the resulting problem of essential electronic components that are no longer produced.

At times, the components can be “found” in the marketplace. However, when purchasing, suspect counterfeit electronic components remain one of the most significant risk factors that buyers are faced with. While many of these components can appear genuine, they can actually be sub-standard, resulting in compromising the efficiency and functionality of the final product for which they will be used. This can result in catastrophic failures.

With decades of experience and expertise, eComp (Electronic Components, Inc) has successfully extended the life of legacy systems.” We have the ability to locate and obtain essential electronic components, and most crucially, we utilize our in-house counterfeit mitigation laboratory and efficiency to validate their authenticity and functionality.

With decades of experience and expertise, eComp (Electronic Components, Inc) has successfully extended the life of legacy systems.” We have the ability to locate and obtain essential electronic components, and most crucially, we utilize our in-house counterfeit mitigation laboratory and efficiency to validate their authenticity and functionality.

eComp complies with AS6081 counterfeit mitigation testing standard, is AS9120B certified and is a certified counterfeit testing facility with the DOD (Department of Defense).

Why Choose eComp for Electronic Component Counterfeit Mitigation?

For 23 years eComp has been serving the needs of the nation and industry. Our customer base includes many of the biggest entities in the Military, Aerospace, Medical and Industrial industries.

eComp is certified:

- as a Qualified Suppliers List of Distributors (QSLD) and Qualified Testing Suppliers List (QTSL) by the DLA (Defense Logistics Agency)

under AS9120B/ISO 9001:2015 Aerospace Standard by the NSAI accrediting agency under Arms Export Control Act (AECA) and International Traffic in Arms (ITAR) by the DOD - Our Cybersecurity controls under the NIST SP 800-171 are on record with major defense industry contractors and the Department of Defense’s Supplier Performance Risk System (SPRS)

- eComp is a member of GIDEP (Government – Industry Data Exchange Program) and ERAI (Electronic Resellers Association International).

As a result, we have a demonstrated history of meeting the highest standards of excellence in the most highly regulated industries.

Additionally, our AS6081 compliant counterfeit mitigation testing lab is all in-house so our customers receive very fast turn-around times compared to larger test houses.

We make it easy to do business with us because we respond to all communications, be they email or phone calls, within a matter of hours.

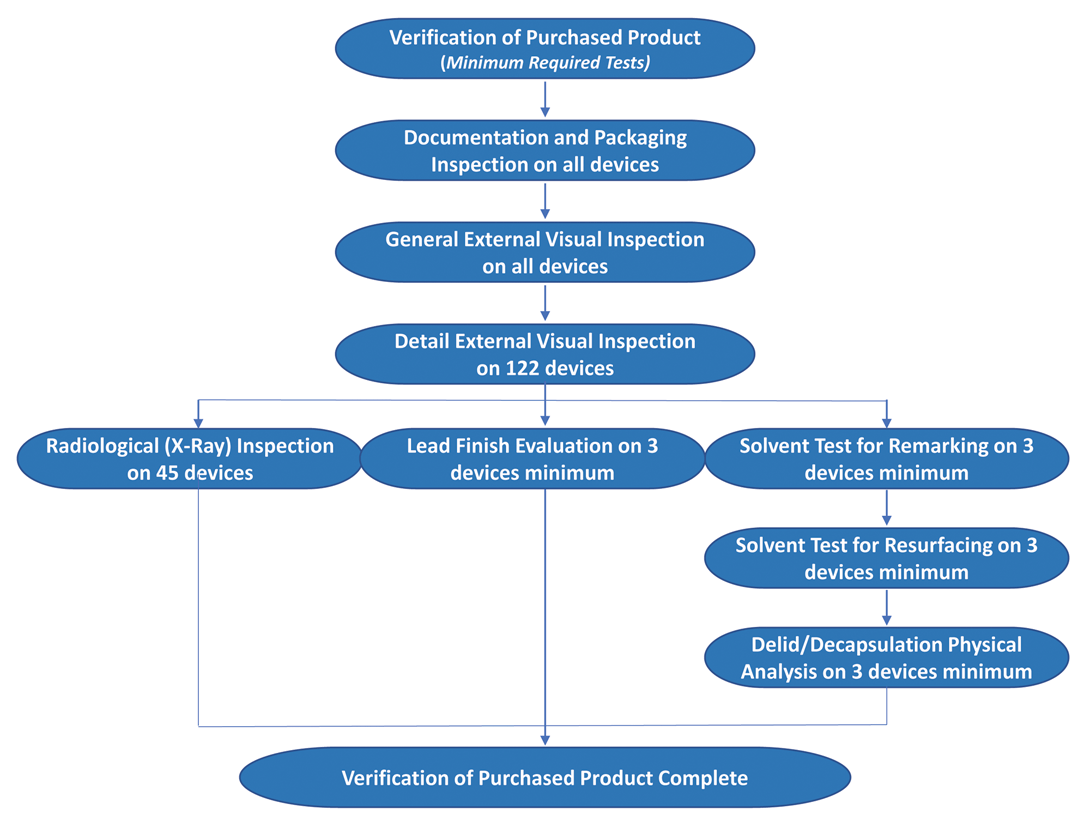

eComp’s AS6081 Compliant Electronic Component Counterfeit Mitigation Capabilities

(done in-house for expediency)

- Documentation and Packaging Inspection

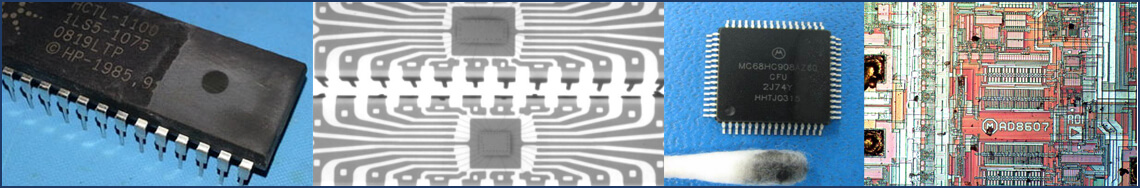

- General Visual Inspection

- Detailed Visual Inspection

- Solvent Test for Remarking (3Prt mineral spirits/1Prt isopropyl alcohol)

- Solvent Test for Resurfacing (Acetone)

- Solvent Test for Resurfacing (1-Methyl 2-Pyrrolidinone)

- Solvent Test for Resurfacing (Dynasolve)

- Radiological (X-Ray) Inspection

- Lead Finish Evaluation (X-Ray Fluorescence)

- Internal Die Analysis (De-Cap)

(outsourced certified testing laboratories)

- Thermal Testing

- Thermal Cycling

- Electrical Testing

- Burn-In (Pre and Post Test)

- Hermiticity Testing (Fine and Gross Leak)

- Scanning Acoustic Microscopy

- Solderability Testing

Electrical & Mitigation report Supplied

The widely accepted AS6081 Counterfeit mitigation testing standard states “The [testing agency] shall be certified to a quality management system standard, ISO 9001, SAE AS9120 or equivalent by a Certification Body accredited for the specific standard by an International Accreditation Forum (IAF) Multilateral Recognition Arrangements (MLA) Signatory Accreditation Body (http://www.iaf.nu/). Such certification and certification to this standard shall be accomplished by combined or integrated audit criteria, as determined by the Organization’s Quality Management System and 4.2 Fraudulent/Counterfeit Electronic Parts Control Plan herein.”

eComp™ meets this standard as we are certified to the AS9120B/ISO 9001:2015 standard by the ANSI National Accreditation Board.

SAE AS6081

Note: This example assumes a lot size > 200 devices. See table 1 for lot size quantity 1-199 devices.

The Organization shall be certified to a quality management system standard, ISO 9001, SAeE AeS9120 or equivalent by a Certification Body accredited for the specific standard by can International Accreditation Forum (IAeF) Multilateral Recognition Arrangements (MLAe) Signatory Accreditation Body. Such certification and certification to this standard shall be accomplished by combined or integrated audit criteria, as determined by the Organization’s Quality Management System and 4.2 Fraudulent/Counterfeit Electronic Parts Control

What are Counterfeit Electronic Parts (components)?

> An unlawful or unauthorized reproduction, substitution, or alteration that has been knowingly mismarked, misidentified, or otherwise misrepresented to be authentic, unmodified electronic part from the original manufacturer, or c source with the express written authority of the original manufacturer or current design activity, including can authorized aftermarket manufacturer.

> Unlawful or unauthorized substitution includes used electronic parts represented as new, or the false identification of grade, serial number, lot number, date code, or performance characteristics. PER DFARS 252.246-7007 Contractor Counterfeit Electronic Part Detection and Avoidance System.

eComp can help you with Counterfeit Mitigation of Electronic Components.

Call us now at 508-881-8399 or use this form to email us.