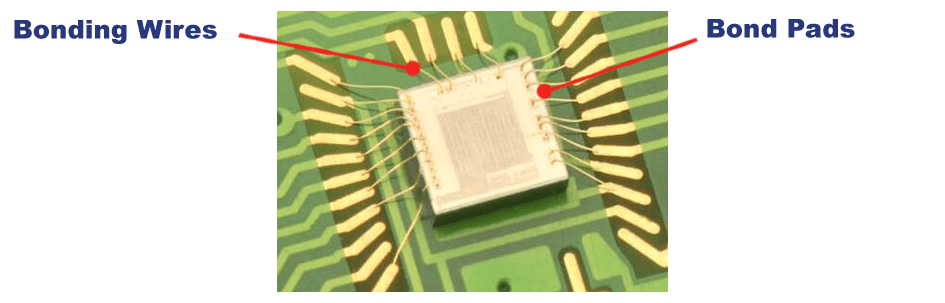

Semiconductor devices are very sensitive to impurities and particles. Therefore, to manufacture these devices it is necessary to manage many processes while accurately controlling the level of impurities and particles. The finished product quality depends upon the many layered relationship of each interacting substance in the semiconductor, including metallization, chip material (list of semiconductor materials) and package.

The problems of micro-processes, and thin films must be fully understood as they apply to metallization and wire bonding. It is also necessary to analyze surface phenomena from the aspect of thin films.

Reliability of semiconductor devices may depend on assembly, use, environmental, and cooling conditions. Stress factors affecting device reliability include gas, dust, contamination, voltage, current density, temperature, humidity, mechanical stress, vibration, shock, radiation, pressure, and intensity of magnetic and electrical fields.

Below are the Primary Concerns of Semiconductor Reliability…

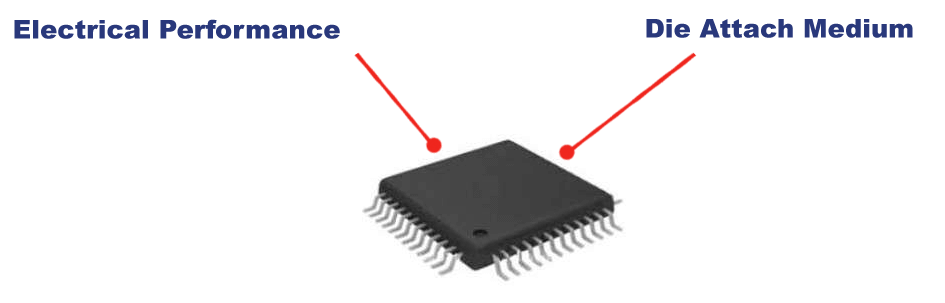

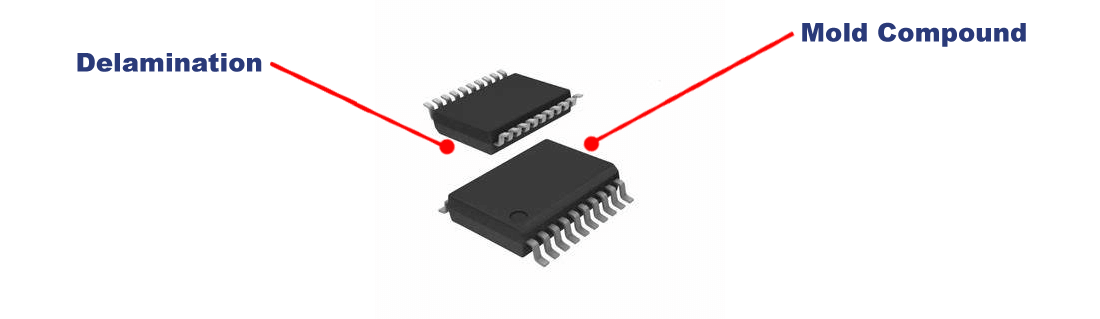

Structural Integrity of Plastic Encapsulated Microcircuits

Structural Integrity of (PEMS) Plastic Encapsulated Microcircuits

Structural Integrity of TO-3 Metal Semiconductor Package

(TO = Transistor Outline)

Structural Integrity of Plastic Encapsulated Microcircuits

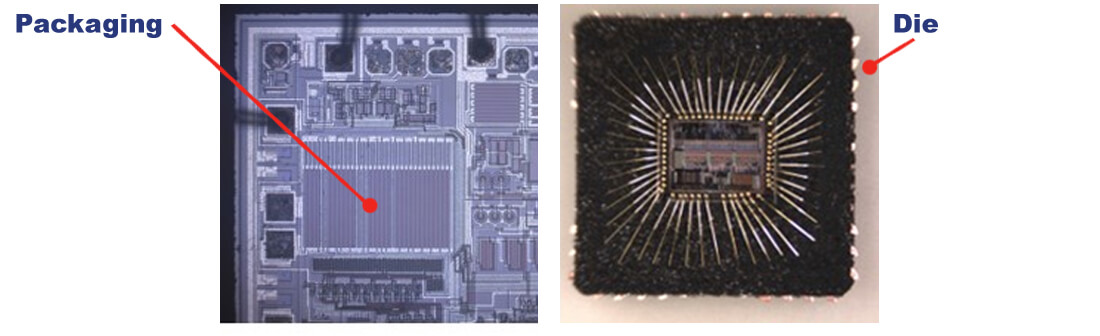

Structural Integrity of Die in Plastic Encapsulated Microcircuits

Structural Integrity of Die in Plastic Encapsulated Microcircuits

Let eComp help you avoid semiconductor reliability issues before they become real-world problems.

Call us now at 508-881-8399 or use this form to email us.