Although quality component sourcing practices help mitigate receiving counterfeit components, the threat of counterfeits is still all too real.

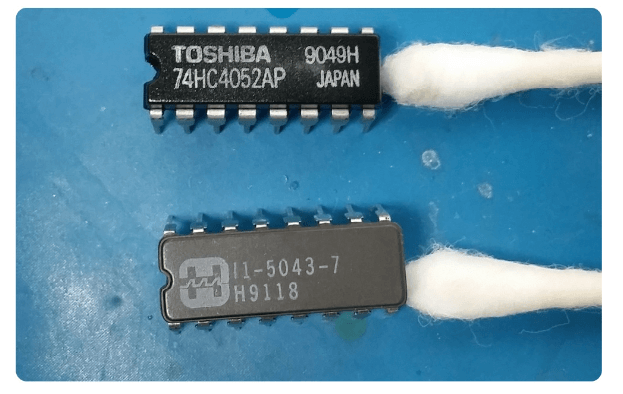

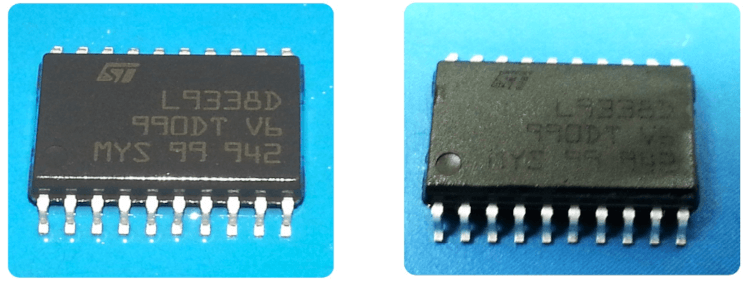

Resistance to solvents testing is an important part of the counterfeit mitigation process which verifies that markings on a device will stay legible, and any surface will remain intact while under exposure to solvents.

In most (but not all) cases, if markings or the surface is wiped away the device is counterfeit. Chemicals used for this include Mineral Spirits, Acetone, 1- Methyl 2- Pyrrolidone, and Dynasolve. Which of these chemicals are heated is dependent on the standard being tested by.

eComp offers Resistance to Solvents testing!

Contact us here for all your counterfeit mitigation needs!