Solution for electronic systems sustainment issue of obsolete parts

Problem Statement: Defense contractor’s airborne sensor platform is in sustainment mode. Designed and in service since 1970 their customer requires a program life extension on the platform. A preliminary design review determined that a critical electronic sensor component, specifically a tiny mil-spec packaged MT-42 transistor was out of production. eComp was consulted to evaluate possible technical approaches to be considered in solving the problem.

Background: eComp is an industry leader in support of legacy electronic systems sustainment. eComp brought in Monzite as a partner in the process. Three possible approaches were evaluated :

- Procure inventory from surviving legacy stock for a lifetime buy and apply AS6081 Compliant Counterfeit Mitigation process to qualify the parts.

- Redesign of the complete sensor with currently available mil-spec components. Estimated cost $400K with a high risk assessment. Project timeline was 12 months.

- Design, procure and assemble a mil-spec form, fit and function replacement part. Estimated cost $50K and low risk assessment. Project timeline was 4-6 months.

Solution: eComp research determined that there was insufficient legacy stock of the mil-spec part to support a lifetime buy of the original part. Additional research revealed no commercially available part that could be up-screened for the requirement. A complete redesign was ruled out due to cost, risk and schedule impact. It was agreed that OEM partner Monzite would design and qualify a military grade component in the original form factor.

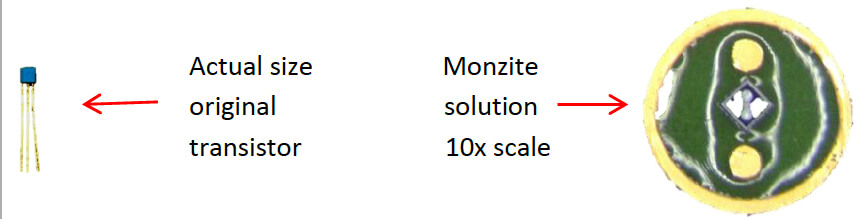

Monzite component engineering applied its unique experience in design and manufacturing of custom hermetic and wire hybrids. The Monzite solution was to procure original 2N4xxx bare die and design a custom package. The package would be a glass/metal seal with the die mounted and wire bonded to the leads. A hermetically sealed stainless steel domed lid would complete the design.

The eComp/Monzite solution was completed in less than 4 months with a final cost less the $50K budget estimate. The $50K project cost included:

1. All NRE on the custom glass seal

2. ALL NRE for required production tooling

3. 150 piece initial quantity order

4. Lifetime supply of bare die for any future requirements

Conclusion: The legacy part/system sustainment process has been complicated by many OEMs ending production of low volume military parts and the proliferation of counterfeit parts offered in some after -market distribution channels. The eComp/Monzite approach enable a risk averse methodology for legacy part sustainment. For an integrated approach that fills the need for low cost, low risk, and low volume eComp/Monzite is your ideal supplier. Give us a call today to discuss how our design and procurement team for specialized legacy components can help in your cost and time sensitive requirements.