Suspect counterfeit parts remain one of the largest risk factors that buyers face when purchasing electronic components. While many of these components appear genuine, they are actually sub-standard and compromise the efficiency and functionality of the final product in which they are used. Even more alarming is the potential risk to human life when these components are expected to perform a function in a system designed to protect the very lives they are now endangering. The solution is Counterfeit Electronic Component Mitigation.

eComp can help OEMS and systems integrators to avoid and identify counterfeit electronic components before their application is ever put at risk. eComp, utilizes up-to-date counterfeit mitigation procedures including electronic component testing and authentication methods to lessen the risk that your company might otherwise face when buying components. eComp complies with all AS6081 Compliant testing requirements and is a certified counterfeit testing facility with the Dept. of Defense.

eComp can help OEMS and systems integrators to avoid and identify counterfeit electronic components before their application is ever put at risk. eComp, utilizes up-to-date counterfeit mitigation procedures including electronic component testing and authentication methods to lessen the risk that your company might otherwise face when buying components. eComp complies with all AS6081 Compliant testing requirements and is a certified counterfeit testing facility with the Dept. of Defense.

eComp’s InHouse Counterfeit Electronic Component Mitigation Capabilities

Non-Destructive Testing

External Visual Inspection – Document and Packaging Inspection

eComp evaluates all supplied documentation to verify its validity, originality, and applicability to the delivered materials. The process also verifies the materials used to ship the devices to make sure that it conforms to industry standards, including but not limited to, shipping material damage, ESD packaging, and moisture sensitivity level packaging.

External Visual Inspection – General and Detailed Inspections

All devices received are first subject to a general inspection which constitutes an inspection of the items to validate their conformity in physicality. All devices must be identical to the unaided eye and have been subjected to the same handling, packaging and storage conditions. The devices must also be identified with identical markings regarding lot code/date code or serial numbers. Parameters exist for the handling of multiple date codes, which can be a common occurrence when dealing with after market or “grey” market parts.

During the detailed inspection, devices are examined at higher magnification and in lighting that is sufficient to detect the entirety of the feature being examined. Aspects of the parts tested include, but are not limited to: part dimensions, packaging type, verification of lead condition, verification of grid arrays, marking discrepancies, package irregularities and conditioning. Any anomalies found are recorded and evaluated in the final testing report.

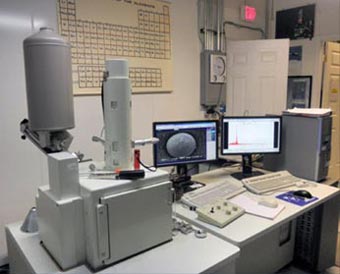

X-ray Inspection

The purpose of X-ray analysis is to verify device conformity within the lot being evaluated by taking particular notice of die size, general shape, lead frame construction, wire bond gauge and routing. The X-ray inspection can also detect ESD and EOS damage within the devices.

Click here to check out our additional InHouse Testing and Reporting

Click here to check out the Primary Concerns of Semiconductor Reliability

Click here for our Up-Screen Flow chart.

Call eComp today and let us help you with Counterfeit Electronic Component Mitigation. Call us at 508-881-8399 or 1-877-463-2667 or email us now.